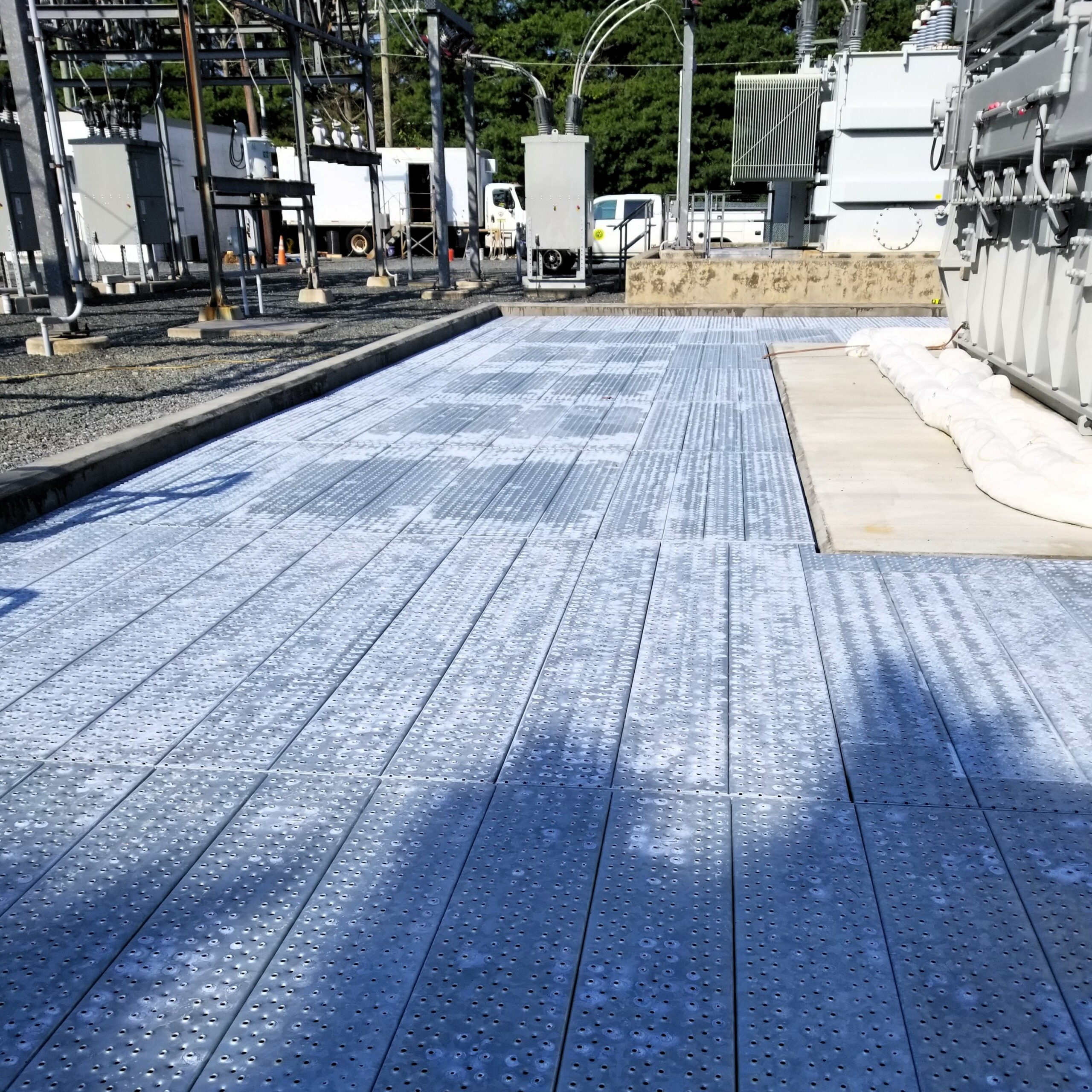

STONEQUENCH™-LHD® Fire-Suffocating Grating for transformer pit

0,00 €

Replace traditional crushed stone, enhance safety, and reduce fire risks

The STONEQUENCH-LHD® fire-suffocating gratings, an innovative solution from NORTHBRIT and SPI, are designed for transformer concrete retention pits to mitigate hydrocarbon pool fire risks. This system blocks oxygen flow to the fuel source through a rigid, perforated structure placed over the containment pit, replacing traditional gravel beds. Tested by independent laboratories, including MFPA Leipzig and SP TRI Borås, it complies with major international and U.S. standards and fire safety recommendations. The STONEQUENCH-LHD system provides rapid fire suppression while maintaining load-bearing capacity, ensuring safety for personnel working around transformers.

Description

Description

STONEQUENCH LHD : increase safety, reduce fire risk, simplify your substation pit

Replacing the traditional stone bed, the STONEQUENCH-LHD® cover is made of custom-engineered, prefabricated LHD® fire-suffocating grating. These gratings are precision-welded into robust panels and frames, which are then mounted on support angles along the upper edges of the containment pit. For larger spans, additional beams are installed to ensure structural integrity.

The result is an industrial-grade 3-in-1 perforated surface that provides:

- Fire suppression: Restricts oxygen supply to effectively extinguish potential fires.

- Non-slip surface: Ensures safe movement for maintenance personnel around the transformer.

- Load-bearing capability: Supports operational loads, such as workers and equipment, ensuring durability and safety.

This advanced system eliminates the need for crushed stones and offers several key advantages:

- Improved fire suppression efficiency through a compact, engineered design.

- Reduced pit size: Its compact design reduces the overall size of the containment pit compared to traditional stone beds.

- Proven passive fire protection: Delivers significant and reliable fire safety performance.

- Enhanced operational safety: Anti-slip properties provide a safer working environment around critical transformer infrastructure.

The STONEQUENCH-LHD® system sets a new standard in fire safety, operational efficiency, and structural reliability for power transformer oil containment solutions.

How does STONEQUENCH-LHD® fire-suffocating grating works?

STONEQUENCH-LHD achieves its effect through a perforated surface that restricts oxygen supply to the fire. The advanced design accelerates the flow of burning hydrocarbons into the pit beneath the grating, outperforming older single or multi-slope damper models in speed and consistency.

Once hot oils are trapped in the pit, the fire self-extinguishes almost instantly due to oxygen deprivation. This rapid suffocation minimizes temperature rise and prevents thermal runaway, effectively disrupting two key components of the fire triangle: temperature and oxygen.

Generic specification of the standard STONEQUENCH-LHD®:

Products and Specifications

- Independent Testing: Tested multiple times by independent laboratories, such as MFPA Leipzig or SP Technical Research Institute of Sweden, with test certificates in the name and ownership of the manufacturer, validated and recorded by the laboratories.

- Load Capacity:

- 500 daN/m² (10.4 lb/ft²) distributed load, per EN-14122.

- Equivalent to 1.5 kN on a 200×200 mm area (337 lb on 7.87×7.87 in).

- Material:

- Made of hot-dip galvanized steel, with a minimum thickness of 3 mm (0.12 in) to ensure deflection under 4 mm (0.16 in), as per EN-14122.

- Optional GALVAGRID® zinc coating for corrosion resistance equivalent to or greater than C5H or C5X.

- Air Passage:

- Maximum authorized air passage of approximately 4.1% to maintain sufficient airtightness and prevent oxygen replenishment under the pit.

- Perforations:

- Hole diameter: 7 mm (0.28 in).

- Approx. 1,065 holes per m² (99 holes per ft²), with 4.1% open surface area.

- Flow Rate:

- Minimum of 660 L/min (174.2 gal/min) for mineral oil at 90°C (194°F) per m² (10.76 ft²) of cover.

- Non-Slip Gratings:

- Hot-dip galvanized steel with certification according to ISO EN 1461:2022 standards.

- Load-Bearing Capacity:

- Standard capacity of 500 daN/m² (10.4 lb/ft²), equivalent to 2 operators and a 200 L (52.8 gal) oil drum.

- Load capacity can be customized to meet specific client requirements and budgets.

Accessories and options

The STONEQUENCH-LHD® system is fully custom-made :

to ensure seamless installation and optimal performance. Upon request, SPI teams or our local agents can conduct on-site measurements. Using your plans or manual site data, our engineering team designs and drafts the complete system, including supporting structures, ensuring exceptional durability and one of the highest resistance ratings (per m² or ft² ) available on the market. For additional details, please consult us.

Optional Accessories for Enhanced Functionality

The STONEQUENCH-LHD® range includes a variety of accessories to meet your specific project requirements:

- SPI Filtration System: For outdoor pits, this system enables continuous drainage of rainwater. It is installed beneath the fire-suffocating cover using a concrete inspection chamber connected to the pit.

- Non-Slip Access Hatches: Provides safe access to filters, SPI pre-filtration cages, or the pit’s base for maintenance and inspections.

- Material Options: Available in stainless steel or treated with GALVAGRID® coating for superior corrosion resistance, achieving or exceeding C5H and CXS standards, particularly in saline or coastal environments.

- MALT Grounding Modules: Equipped with braids and lugs for grounding; custom sections can be specified for quoting.

Key Benefits of STONEQUENCH-LHD®

- Tailored Design: Custom-fit to your project, ensuring precise integration and efficient fire suppression.

- Structural Excellence: Designed to withstand heavy loads while maintaining exceptional fire safety standards.

- Comprehensive Solutions: Includes drainage, corrosion resistance, grounding, and maintenance access options to ensure a complete, reliable system.

- Innovative Technology: Engineered for rapid fire suppression and passive safety by targeting critical components of the fire triangle.

The STONEQUENCH-LHD® system is a versatile and highly efficient solution for modern transformer oil containment pits, ensuring compliance with stringent safety and performance standards.